Chemicals play an important role in the semiconductor manufacturing process, and their grade has been clearly shown to affect the yield of back-end products. SEMI C1 "GUIDE FOE THE ANALYSIS OF LIQUID CHEMICALS" also clearly regulates the specifications and verification standards of these chemicals, including purity, color, PH value, metal concentration, etc.

Chemicals are often used in etching stations and cleaning stations in the semiconductor manufacturing process, and metal impurities in the chemicals will diffuse into the wafer or remain on the wafer surface at these stations. Metal-contaminated wafers When it reaches IC components, it will cause leakage current in the p-n structure, which will lead to the collapse of the oxide and reduce the voltage, which is harmful to IC components.

Therefore, we strongly recommend that manufacturers monitor the impurity concentration of the chemicals themselves to maintain product stability during the manufacturing process. Monitoring opportunities include the following processes:

• Evaluation of new raw materials;

• Incoming material inspection;

• Central plant supply (water, chemicals) system monitoring.

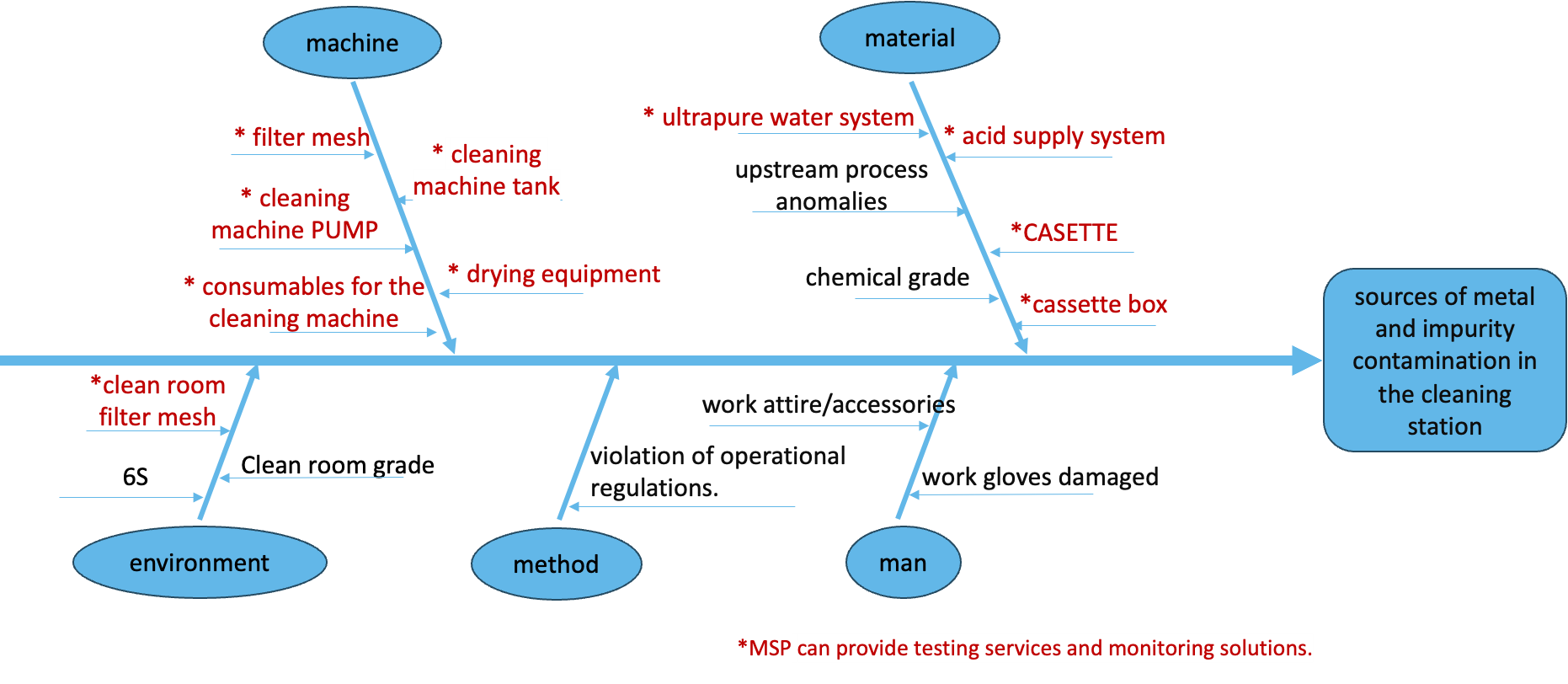

Using a fishbone diagram to analyze the pollution sources at the cleaning stations that use the most chemicals can make it clearer:

Two examples are shared below:

• Case 1:

In 2022, a semiconductor factory provided acid for the entire plant from the factory's central acid supply system. An acid supply PUMP failed and was replaced. After that, metal contamination appeared in the end product monitoring one day. In order to clarify the situation, the process end It took several days and countless experiments to confirm the problem, and finally the source of the problem led to a problem with the acid supply PUMP.

• Case 2:

In 2019, a major integrated circuit manufacturer had major wafer defects and scrapped 100,000 wafers, resulting in a shortfall of approximately US$550 million in quarterly revenue. After a subsequent investigation, it was discovered that the chemical process provided to a certain supplier had changed. This has caused serious yield problems in wafers manufactured by major integrated circuit manufacturers.

Prevention is better than remediation

Everyone who is at the forefront of technology needs to prioritize quality in their hearts at all times

The team members of Shangwei Technology have been working in semiconductors for many years. In addition to their extensive experience, we are also well aware of the impact that chemicals may have on the production process of the semiconductor industry. Therefore, Shangwei Technology can not only provide customers with chemical raw materials Our testing services can also provide customers with appropriate monitoring solutions, because semiconductor process monitoring is our strength.

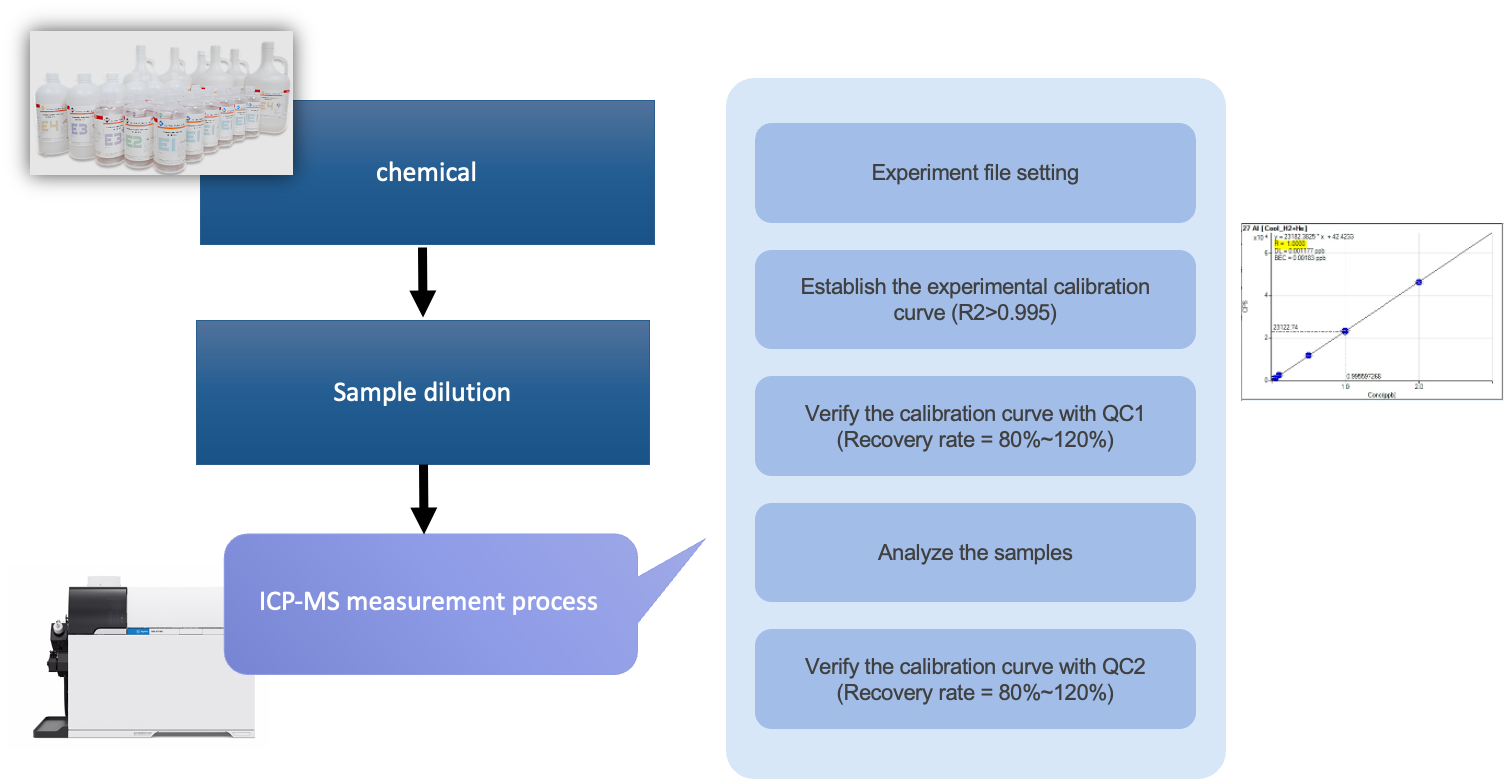

Shangwei Technology’s inspection procedures for chemicals are briefly introduced as follows:

Reagent preparation:

• Resistance>18.2 MΩ-cm ultrapure water

• Ultra-pure grade chemicals with impurity concentration <10ppt

The operation process is as follows:

Chemicals are a very important part of semiconductors and directly affect the quality of products, especially the more advanced processes; the higher the level required by the semiconductor industry, the higher the degree of impact. Once a chemical abnormality problem occurs, more than one customer is usually affected, and the extended losses may be difficult to estimate, not to mention the possibility of damage to the company's reputation and loss of customer trust.

From raw material inspection to the water supply system on the factory side to cleaning consumables on the equipment side, Shangwei Technology can provide monitoring solutions and services based on key points, providing one-stop services to reduce customer troubles and thereby improve product quality.

Shangwei Technology can provide customers with more than 40 element testing results to help customers obtain more complete information; if you have needs for metal element testing and analysis of raw materials, please feel free to contact us!

Inquiry mailbox x

Inquiry mailbox x